PSP-LT140-IS

Product Description

PSP-LT140-IS is a screen printable silver paste that is used for membrane switch, display, sensors, thin film PV and general printed electronics applications. The paste is compatible with low temperature substrates such as polycarbonate, paper and PET due to its low curing temperature (60-140˚C). The paste can also be dried at room temperature over a 12 hour period.

Product Benefits

-

Low temperature sintering temperature (60-140˚C)

-

Excellent electrical conductivity (<8 mΩ/□/mil)

Paste Preparation

PSP-LT140-IS is a single part paste system. Once the paste has been removed from the container for printing, this may introduce contamination.

Please do not replace the paste in the container. The paste should be gently stirred before use avoiding incorporation of air bubbles.

Properties of Uncured Paste

|

Test |

Properties |

Viscosity after mixing (Pa.s)

(Cone & plate, 50s-1, 20oC) |

5-15 |

|

Screen residence time |

Please add diluent after 2 hours if the paste has not been used to compensate for solvent evaporation losses and ensure consistent printing. |

|

Thinner |

For slight adjustments in viscosity, please contact us. |

|

Coverage |

180 cm2/g |

|

Solids Content |

75-78 % |

Paste Processing Conditions

|

Parameter |

Typical Properties |

|

Substrate |

PC, PET |

|

Screen |

325 SS, 13 µm emulsion |

|

Flood speed |

50 mm/s |

|

Print speed |

30 mm/s |

|

Squeegee type |

90A Shore |

|

Squeegee Pressure |

3.5 kg |

|

Squeegee holding angle |

60º |

|

Squeegee Length |

220 mm |

Once printed the silver paste should be left in ambient for 5min to allow levelling. The paste can be dried using either a convection oven or using IR heating. Typical drying parameters used are 90ºC for 30 mins or 120ºC-140ºC for 10 mins. Drying times may be reduced to achieve the optimum resistivity depending on manufacturing process set-up.

Properties of Cured Paste

|

Test |

Typical Properties |

|

Sheet Resistance |

<8 mΩ/ □ /mil |

|

Volume Resistivity |

<22 µΩ.cm |

|

Adhesion |

5B |

|

Resolution (L/S) |

100 µm |

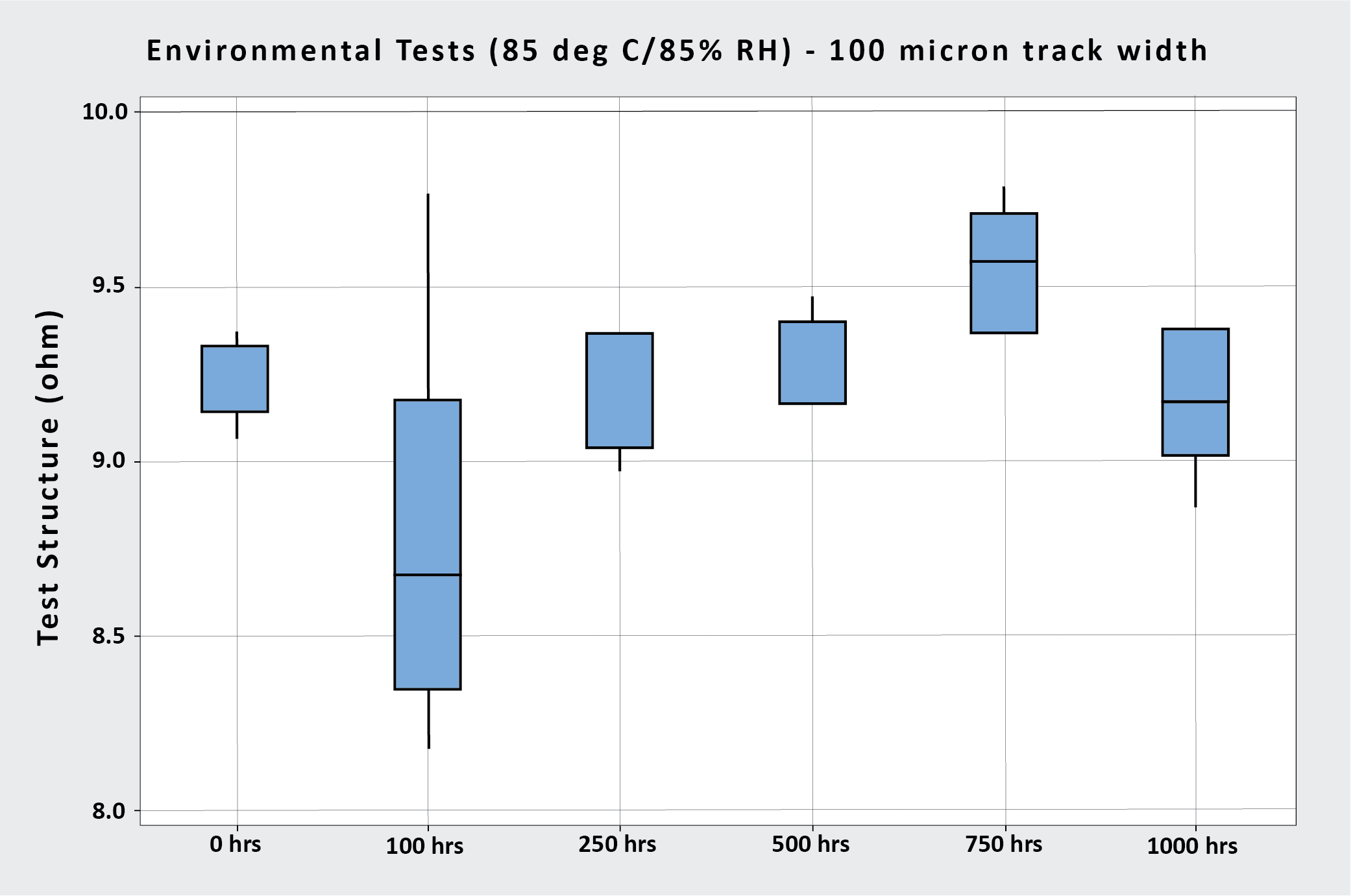

Reliability Data

Clean-Up

Clean-Up

Equipment can be cleaned using ketones such as acetone.

Storage and shelf-life

For optimum results, the containers should be stored in a fridge (4˚C) with lids tightly sealed. The paste shelf-life for an unopened container is 6 months from date of shipment. Please ensure the material has time to reach room temperature before use. Avoid introduction of water into the paste.

Safety and handling

For safe use of this product, please review relevant material safety and datasheet (MSDS).